TZM Hot Runner Application

Introduction

Hot runner system originated in the injection molding industry no runner system. As an advanced plastic injection molding technology, the working mechanism is using electric heating method to make sure the plastic to maintain molten state in hot runner. Hot runner also known as runnerless means after each injection the molten plastic will not coagulate so when the plastic product release will not take off the gates. Since the molten plastic did not freeze in the runner, so it is conductive to next time injection. In a word, hot runner is an extension of the injection molding machine of hot runner nozzle. Currently, many plastic mold factories using a mold hot runner technology for more than 50% plastic products production, and some mold factories even more than 80%. Mainly because using hot runner system can shorten the molding cycle of plastic products, saving plastic raw materials, reducing waste, improving product quality, and help expand the application range of injection molding processes.

Application

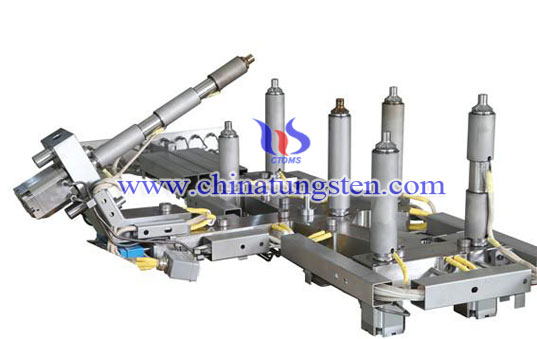

With TZM hot runner technology matures, its application areas have gradually expanded. Hot runner in the automotive, home appliances, electronics, medical and industrial and other fields has widely used.

Auto parts production: TZM hot runner can greatly improve the accuracy of the plastic parts which can be used in automobile trim system and engine components production, for example, car bumpers, instrument panels, window cloth trim, lamp cover, door plank and other parts production.

TV components: using hot runner for TV components production has good performance and better quality, so manufacturers usually use it to produce beautiful front bezel, hard rear cover and solid frame and chassis of television.

Mobile phone: hot runner also commonly used in small plastic parts production, such as smart phones plastic front cover, back cover and other parts production.

Office Supplies: Office supplies has high requirements on material’ appearance, firmness and durability, so manufactures usually use hot runner system for office supplies production.

Household appliances: household appliances have high requirements on products’ appearance, firmness and durability. Using hot runner system can produce handsome and high quality products.

Packaging industry: in the packaging industry, plastic products application range is very extensive and the plastic products which produce by hot runner can meet packing industry using requirement.

Medical industry: Plastic products used in the medical industry are also very wide, using hot runner for medical plastics production with better precision and better performance.

Industrial field: industrial market are increasingly turning to more thin, durable and affordable plastic products, using hot runner for plastic products production can save raw materials, reduce costs, but also has high efficiency and short cycle times, suitable for industrial plastic products production.