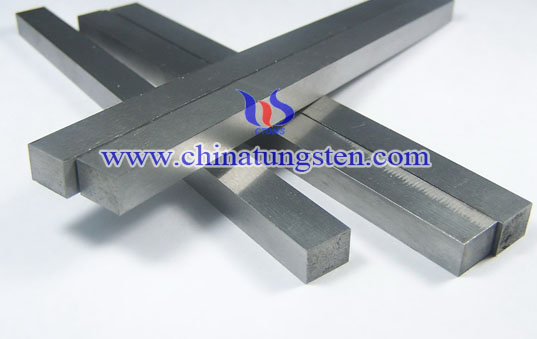

Hot Runner TZM Bar

Introduction

Titanium zirconium molybdenum (TZM) alloy is doped with a small amount of metal trace elements titanium (Ti), zirconium (Zr) and carbon (C) on the basis of the molybdenum substrate, obtained by powder metallurgy method. These trace elements will react with molybdenum (Mo) to produce solid solution strengthening and second phase strengthening, and then through a series of processing improve alloy’s deformation strengthening, so TZM alloy has better mechanical properties and high temperature properties than other molybdenum alloy. TZM alloy is widely produced into various shapes, such as tube, block, plate, sheet, rod, bar and other special shape as a high temperature parts used in various fields and in hot runner system field is more popular.

Hot runner system is a combination, which includes nozzle, runner plate, temperature controller, spreader plate and so on. Hot runner as common component in injection molding system to ensure plastic remains molten in runner and the gate is by heating. Hot runner often uses at high temperature, and TZM bar has good high temperature performance, so often as a raw material for hot runner, hot runner nozzles and other system components production.

Classification

Hot runner TZM bar is usually used for hot runner production, and its surface showing silver metallic luster. Hot runner TZM bar according to the degree of processing can be divided into different types, such as sintered TZM bars, forged TZM bars, polished TZM bars and so on.