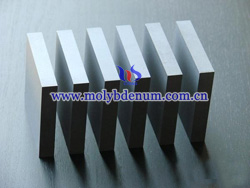

Molybdenum Magnetron Sputtering Target

Molybdenum magnetron sputtering target operating principle is the electron under the action of electric field E, in the process of flying to the substrate collision with the argon atoms to ionize and to produce Ar positive ions and new electrons. The new electrons fly to the substrate and Ar ions under the action of electric field accelerated fly to the cathode target with high-energy bombardment on the target surface, so that to make the target sputtering.

In the sputtering particles, the neutral target atoms or molecules deposited on the substrate to form a thin film. On the other hand, the generated secondary electrons are subject to electric and magnetic fields, resulting in E (electric field) × B (magnetic field) drifting, and its trajectory is similar to magnetron sputtering cycloid. In the case of annular magnetic field, electrons will do circular motion with approximately cycloid form on the target surface and their motion path is not only very long but also bounded in the plasma region near the target surface. Besides, in this region will ionize a large amount of Ar to bombard the target, thereby achieving high deposition rate. With the increase of the number of collisions, the energy of the secondary electrons is exhausted, and gradually away from the target surface, and finally deposited on the substrate under the action of the electric field E.

Molybdenum magnetron sputtering target has high strength, high temperature, wear resistance, corrosion resistance and other excellent performance. The purity is 99.95% and density is 10.2 g/cm3. Melting point is 2610 ℃ and boiling point is 5560 ℃. According to the shape the molybdenum target types include rectangular magnetron sputtering target, circular magnetron sputtering target and cylindrical tube magnetron sputtering target. Sputtering targets are mainly used in electronics and information industry, such as integrated circuits, information storage, liquid crystal display, laser memory, electronic control devices. In addition, it can also be applied to the field of glass coating and can also be used in wear-resistant materials, high temperature corrosion, high-end decorative products and other industries.

If you have got any interest in molybdenum metals, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.

Related Links: Molybdenum News & Prices