Molybdenum Wire for Furnace Components

Molybdenum wire for furnace components is specifically designed for use in high-temperature environments such as vacuum furnaces, inert gas furnaces, and industrial heat treatment systems. With an ultra-high melting point and excellent thermal stability, it is ideal for manufacturing heating elements, hangers, supports, electrodes, and internal heat field components in demanding thermal applications.

1.Key Features

Ultra-High Melting Point (2620°C): Ensures integrity in extreme temperatures

Excellent Creep Resistance: Maintains dimensional stability during long-term heating

Outstanding Thermal & Electrical Conductivity: Promotes uniform heating and efficient energy transfer

Chemical Stability: Resists oxidation and gas corrosion under vacuum or inert atmospheres

Precise Dimensions & Clean Surface: Suitable for precision thermal field assembly

|

|

2.Typical Applications

Heating wires in vacuum or controlled atmosphere furnaces

Electrode leads, suspension wires, and support frames for internal furnace parts

Thermal components in sintering, brazing, and annealing systems

High-temperature components in crystal growing and semiconductor annealing furnaces

3.Technical Specifications

| Material | High purity molybdenum (≥99.95%) |

Diameter Range |

0.1 mm – 3.0 mm (customizable) |

Forms |

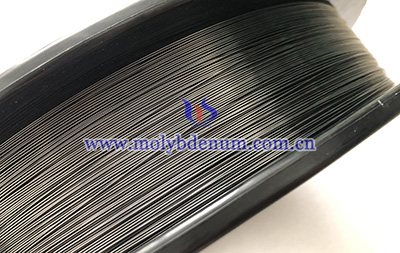

Coil, straight rod, cut length |

Surface Finish |

Cleaned, polished, or black |

Operating Environment |

Vacuum, high-purity hydrogen, argon, and other inert atmospheres |

If there is any inquiry of molybdenum, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.