Molybdenum Production Processes

Molybdenum production processes include molybdenum powder and molybdenum products production process.

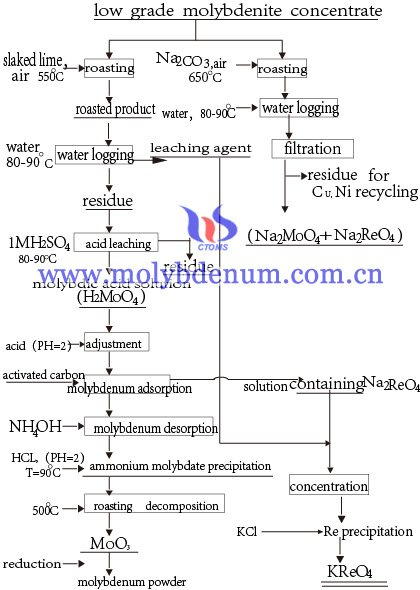

Molybdenum powder production processes are as follows: baked molybdenite to produce ammonium molybdate, use ammonium molybdate as raw materials after calcination to obtain molybdenum trioxide (MoO3), and then through the hydrogen reduction to obtain molybdenum powder. The specific production process is as follows:

Molybdenum finished products production processes will take molybdenum rod as example. Molybdenum rod main production method is powder metallurgy and its production processes are as follows: mixing powder (the lubricant or other elements mixed evenly with raw materials) - Mo powder isostatic pressing ( molybdenum powder to form compact with certain shape, size and strength ) - pre-sintered (compacted molybdenum billet strength and electrical conductivity all poor, to process pre-sintering can enhance its strength and conductive, which is good for high temperature sintering ) - sintering (powder compact in the appropriate temperature and atmosphere, the powder particles will bond to shrinkage and densification, so enhance the sintered body strength.) – subsequent machining - molybdenum rod.

If you have got any question or inquiry of molybdenum, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.