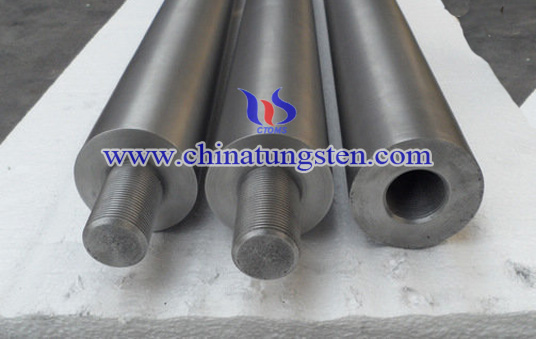

Electric Boosting Molybdenum Electrode

Introduction

Electric boosting molybdenum electrode is kind of electrode material used in an electric boosting furnace. Glass electric boosting furnace is using fossil fuels to melt glass and at the same time to introduce electric energy produce "Joule response" to auxiliary heat molten glass. This system called supplement electric heating system, referred to the electric boosting system (Boosters).

Molybdenum Electrodes has high temperature, stable chemical, good invasion in glass and strong current-carrying capability, so as the first choice among different electrode material. Molybdenum electrode at room temperature whether in air or water is stable, but when the temperature reaches to 400 ℃, a slight oxidation occurs. When the temperature reaches to 600 ℃, there are intense oxidation and will produce MoO3.

Therefore, the electrode must be used with matching electrode water jacket. If coated with anti-oxidation coating on the molybdenum electrode, the oxidation resistance of the electrode will be better.

Electric Boosting Molybdenum Electrode Manufacturing

Electric boosting molybdenum electrode production processes are as following: 1. The ammonium molybdate after sintered becomes molybdenum trioxide. 2. Passing hydrogen and heating molybdenum trioxide so it can reduce to molybdenum powder. 3. The molybdenum powder at 200 ~ 300Mpa pressure pressed by HIP to produce molybdenum powder compact with a certain density and strength. 4. Molybdenum powder compact is sintered in the intermediate frequency induction furnace and protection by hydrogen to produce molybdenum sintered blank. 5. Molybdenum sintered blank under hydrogen protection forging, warm forging to produce molybdenum electrode blank. 6. After a series of machining obtains molybdenum electrodes.