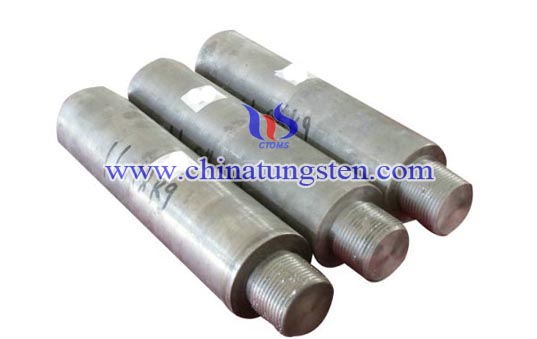

Molybdenum Glass Melting Electrode Production Process

Introduction

Molybdenum glass melting electrodes mainly use powder metallurgy method for manufacturing. Firstly, mix raw material powder evenly, after pressing, sintering to obtain sintered molybdenum blank bar. Then after multi swaging, recrystallization annealing, drawing, straightening, polishing and other machining obtains electrode with different specifications. High quality molybdenum electrode not only is good for high quality glass production, but also can prolong electrode and glass furnace’s service life.

Molybdenum Electrode Production Process

1. Heating molybdate to obtain molybdenum trioxide; 2. Passing hydrogen, heating molybdenum trioxide to obtain molybdenum powder; 3. At 200 ~ 300MPa, using isostatic cool pressing devices for powder pressing; 4. Sintering at hydrogen intermediate frequency induction furnace to obtain molybdenum sintered blank; 5. Sintered blank forging and warm forging under hydrogen protection to obtain molybdenum electrode blank. 6. Machining to obtain molybdenum electrodes.