Molybdenum Glass Melting Electrode Application

Introduction

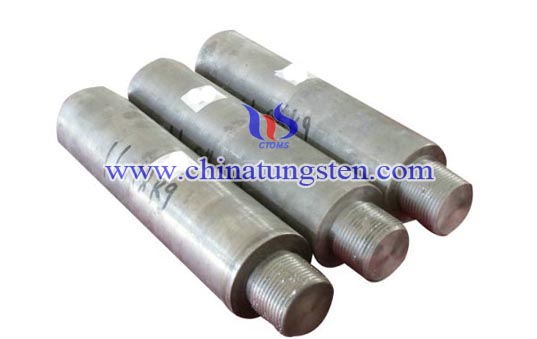

Molybdenum glass melting electrodes, also known as molybdenum electrode. It has a lot of good properties, so it has large application field. Molybdenum Electrodes is widely used in electric glass furnace.

Application

1. Platinum Drawing Furnace Glass fiber is an important building materials and electrical materials. And it is usually uses Pt-7Rh as crucibles, and leads to a large current, so crucibles can reach very high temperatures to melt the glass. However, Pt-7Rh as crucible is expensive, which can not use for industrialized mass production. According to the characteristics and excellent properties of molybdenum glass melting electrodes, using molybdenum electrodes and natural refractories in platinum drawing furnace, not only can save large amount of platinum and rhodium, but also more affordable.

2. GRC Fiber

Glass fiber reinforced cement (GRC) composites are a new type of building material. There are 10%~20% ZrO2 in the fiber and its melting temperature is up to 1500 ℃, so it can only be produced by electric melting method. To produce a largest molybdenum electrode which has effective conductive area 2800 ~ 5000cm2 can use for GRC fiber production and the price is reasonable.

3. Molybdenum Electrodes Used in Aluminum Silicate Fiber Melting Furnace Aluminum silicate fiber felt is high temperature insulation material, and melting temperature of fiber is up to 1700 ~ 1800 ℃, so can only produce by electric melting method. And molybdenum electrode is widely used in electric melting furnace.

Molybdenum Electrode Used For Optical Glass Production In glass products, optical glass has high requirement. Translucentcy and uniformity is an important factor for glass optical quality. Optical glass can be colored or be contaminated, and the melting temperature allowing fluctuations only ± 2 ℃, so only use electric melting method can produce high-grade lenses. In electric melting furnace, molybdenum electrode quality is the key to the production of high-performance glass.