Molybdenum Electrode Used for Rare Earth Industrial

Introduction

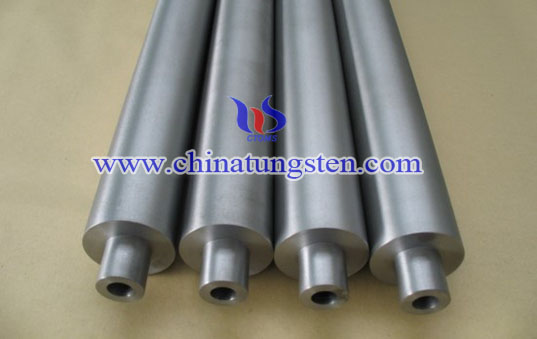

Molybdenum electrode having high temperature strength, high temperature oxidation resistance, corrosion resistance and good thermal conductivity properties, and long service life, commonly used in glass furnace for daily-used glass, optical glass, insulation material and glass fiber produce. In addition, molybdenum electrodes are also commonly as heating component used in the rare earth industry and other fields. High density and low impurity content of molybdenum electrode d is an important factor for rare earth metallurgy, and therefore during molybdenum electrodes production should to strictly control the density and impurity content. Internationally molybdenum electrode component content is 99.95%, density greater than 10.15g /cm3, in order to ensure the quality rare earth and life of electrodes.

Methods for Rare Earth Metallurgy

There are two methods for rare earth metallurgy, hydrometallurgical method and pyrometallurgical method.

Rare earth hydrometallurgy method is a chemical metallurgy way, the whole process mostly in the solution and solvent, such as the decomposition of rare earth concentrates, rare earth oxides, rare earth compounds, single rare earth separation and extraction process operate at precipitation, crystallization, oxidation-reduction, solvent extraction and chemical separation processes. Industry production common uses organic solvent extraction method. This is the common processes for separation high-purity single rare earth elements. Hydrometallurgical has complex process, but the product has high purity and the finished products has widely application.

Pyrometallurgical has simple process and high productivity. Rare earth pyrometallurgical method includes silicon thermal reduction method for rare earth alloy production, molten salt electrolysis method for rare earth metals or alloys production, metal thermal reduction method for rare earth alloys prodution. The common feature of these method is produced under high temperature conditions.