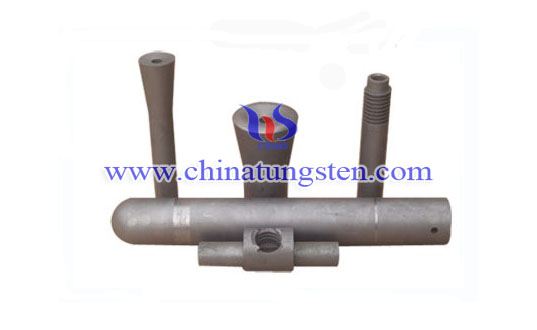

Molybdenum Electrode Used for Domestic Glass Manufacturing

Introduction

Domestic glass refers to common glass products seeing in our daily life, including window glass, glass tableware and glass vases and other household glassware. Manufacturers usually use glass melting furnace for glass meting, which includes a series of physical, chemical and physical and chemical reactions and phenomena. The production process are as following: ingredients preparing-mixing–placing in furnace-forming silicate (600~900 ℃)-glass forming (1200~1250 ℃)-clarification(1400~1500℃)-homogenizer(molten glass long time at high temperature, its chemical composition tends to be uniform)-cooling.

Molybdenum electrodes have good high temperature properties, corrosion resistance and thermal conductivity, so often used as an electrode material for melting glass, widely used in glass furnace. High-quality molybdenum electrodes have great significance for safety using glass furnace and obtaining high quality glass. Density high and homogeneous, while small impurity content of the molybdenum electrode can be obtained high transparency, good quality glass products. In addition, excessive impurity content of molybdenum electrode can also lead to reduce service life. Iron and nickel electrodes impurity content of electrode is too high will cause electrode erosion by molten glass, resulting in electrode breakage, and it will reduce the life of the furnace as well.

Molybdenum Electrode Requirements on Domestic Glass Production:

Molybdenum electrodes should meet the below requirements, so it can produce high quality domestic glass without damaging furnace electrode and reducing electrodes life.

1. High temperature resistance, the electrode should withstand 1700 ℃ high temperatures; 2. The electrode can not oxidized by air at 800 ℃; 3. The electrode should have good conductivity, which should equal to the metal; 4. The electrode should have sufficient mechanical strength at 1700 ℃; 5. The electrode should have good wettability in molten glass; 6. The electrode should has good corrosion resistance, which can withstand the erosion of molten glass; 7. The electrode should have stable chemical and physical properties, which will not pollute the glass.