Glass Molybdenum Electrodes

Glass molybdenum electrodes are formed by isostatic pressing, forging to various types after sintering with medium frequency furnace and then turning, rolling, planning and milling. The max diameter of rod-shape sheets is up to 100mm. we are able to offer different kinds of these products as your requirements

Electrical heating and boosting with glass melting molybdenum electrodes have set a new standard within the industry for efficiency in glass production:

- homogenous temperatures in the glass tank

- improved glass quality

- increased productivity

- higher flexibility regarding tonnage output

- environmentally-friendly production with reduced CO2 emissions

Wherever operating temperatures and chemical requirements exceed the limits of conventional materials such as iron, copper, or nickel - molybdenum stands out with unique properties:

- high material strength at high temperatures

- good electrical conductivity

- excellent corrosion-resistance against molten glass

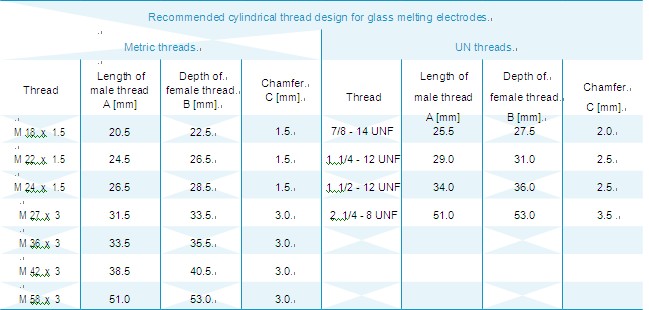

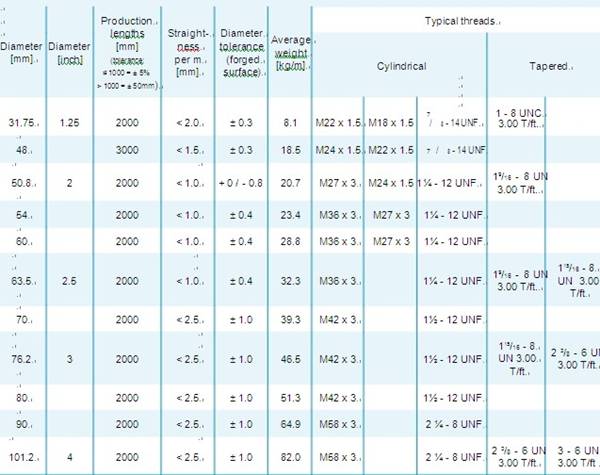

Standard dimensions and thread types for glass melting electrodes

If you have got any interest in molybdenum metals, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.

Related Links: Molybdenum News & Prices