Molybdenum Electrode and Tungsten Electrode

Molybdenum electrode and tungsten electrode both have high temperature resistance, corrosion resistance, and good mechanical properties electrode material, but the applications of them are different. Molybdenum electrodes are used in glass furnace usually as heating equipment for glass production and tungsten electrodes are used for TIG welding.

Molybdenum electrode has high temperature strength and corrosion resistance. Besides, it has excellent mechanical properties and long service life, so often used in glass furnaces, for daily glass, optical glass, insulation materials, glass fiber and other glass products production. The main component of molybdenum electrode is molybdenum, obtained by powder metallurgy process. International common molybdenum electrode molybdenum component content is 99.95% and density is greater than 10.15g/cm3, in order to ensure the quality of glass and electrode life. Commonly used molybdenum electrode size is from diameter 20mm to 152.4mm and single length can reach 1500mm.

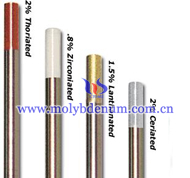

Tungsten electrode is widely used in TIG welding, cutting and plasma welding and other fields. To add a certain amount of rare earth oxides into tungsten can stimulate its electronic work, so tungsten electrode welding performance can be improved and it has stable arc performance and arc column, smaller burning rate. Common rare earth additives are cerium oxide, lanthanum oxide, zirconium oxide, yttrium oxide and thorium oxide and so on, and through the powder metallurgy method can be obtained cerium tungsten electrode, tungsten lanthanum electrode, zirconium tungsten electrode and thorium tungsten electrode.

If you have got any interest in molybdenum metals, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.

Related Links: Molybdenum News & Prices