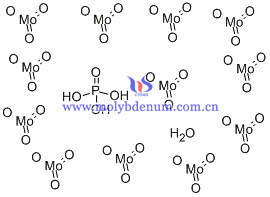

Phosphomolybdic Acid Hydrate Production Processes

Phosphomolybdic acid production processes are relatively simple, usually used molybdenum trioxide as raw material, after reaction can obtain green solution. After solution cooled, centrifugal separation can obtain phosphomolybdate acid hydrate crystals.

Production processes are as following:

1. Put the molybdenum trioxide into reactor, to add water by mass ratio which is molybdenum trioxide: water = 1: 10, with evenly stirring, then to add 85% phosphoric acid (molybdenum trioxide: phosphoric acid molar ratio of 12: 1 ), to boil for 3 hours. The reaction equation is as follows: 24MoO3+2H3PO4+3H2O=△=2(H3PO4·12MoO3)

2. Before reaction the solution is white and the early reaction is golden yellow. The latter response is green. During the reaction should to keep the solution stable to boil and to maintain liquid level. Besides, in the latter response the PH value should control at 1.0.

3. After vacuum filtration to remove residue, to add 30% hydrogen peroxide in the solution can obtain yellow solution.

4. After evaporation and concentration, the solution temperature reached to 105 ℃ to cool the solution.

5. The solution after slowly cooled to crystallize and after centrifugal separation can obtian phosphorus molybdate crystals

If you have got any question or inquiry of molybdenum, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.