Silicomolybdic Acid Production Processes

Silicomolybdic acid production processes are as following:

1.To dissolve 50g sodium molybdate in 200mL water, and the solution was heated to 60 ℃.

2.To add 20mL concentrated hydrochloric acid into the solution with vigorously stirred by mechanical stirrer, and then to add 5g sodium silicate, to continue stirring, 60mL concentrated hydrochloric acid was added drop by drop into the solution by dropping funnel, to filter out the little silicate precipitate by glass asbestos filter. The filtrate was cooled and extraction by slight excess of ether.

3. The solution is easy to form emulsion with diethyl ether, and therefore only very slightly shaken them together and is best to take rotary shaker. If there is emulsion, we can pass into the air stream to clean and destruction. The ether complex can use half of the volume of water to dilute and to discharge it by air flow. If the solution turns green, we can add a little concentrated nitric acid and to make solution turns to yellow.

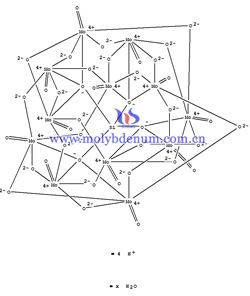

In order to obtain purity product, the product can dissolve in 50mLwater and 15mL concentrated hydrochloric acid mixed solution, and then to extract with ether. If the ether is clean, at 40 ℃ can obtain yellow concentrated liquid. If the product restored by dust, can add little concentrated nitric acid oxidation to restore it to original yellow. The crystalline product contains about 29 crystal water molecules. To heat at 40 ℃ heat for 3 to 4 days, or to put in the dryer for drying, can remove most of crystal water, so the product contains only five or six molecules of water.

If you have got any question or inquiry of molybdenum, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.