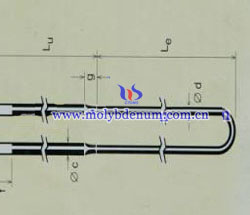

U-shaped Molybdenum Disilicide

U-shaped molybdenum disilicide is one of commonly shape of molybdenum disilicide. Silicon molybdenum rod heating element maximum using temperature is 1800 ℃. It can be made of different shapes, including U-shaped, W-shaped, L-shaped, straight rod shaped and other shapes. The silicon molybdenum rod product parameters are as follows: silicon molybdenum rod (MoSi2 heating element)formula: MoSi2, physical and chemical properties: density: 5.5 ~ 5.6g/cm3, flexural strength: 15MPa (20 ℃), the Vickers hardness (HV): 570kg/mm2 porosity: 7.4%, water absorption: 1.2%, the thermal elongation: 4%, the radiation coefficient: 0.7 to 0.8.

In high temperature furnace, it operation temperature is between 1300℃-1800℃. Generally, the chuck temperature should not exceed 200℃. The contacting voltage of chuck and wire should below 0.1V. In order to avoid radiant heat to pass to the chuck, the distance of chuck lower end and brick upper end should not less than 50mm. Molybdenum disilicide heating element resistance will not affect by operation time, so old and new elements can be mix used in furnace. Moreover, to avoid damage the diameter of 6 / 12mm elements can not be long-term used in 170A current and diameter of 9 / 18mm elements can not be long-term used in 300A current. To ensure the furnace temperature and heating element withstand load evenly should match at the first and each silicon molybdenum rod resistance deviation should not more than 10%. At the same time, since it has little resistance during operation, so it is usually used in low voltage, high current environment for smoothly operation should use the transformer. The transformer is generally thyristor. According to silicon molybdenum rod heating elements calculations power we will know, silicon molybdenum rod power is related to the size. In the same size, the diameter of the hot ends is thicker, the greater the power.

![]()

U-shaped molybdenum dicilicide is most commonly used in a high temperature furnace and its main feature is heat end welded to the cold end and the cold end diameter is double size to the hot end. Standard specifications are: 1700: dxc: Φ3 / 6, Φ4 / 9, Φ6 / 12, Φ9 / 18, Φ12 / 24 and other specifications, 1800: dxc: Φ3 / 6, Φ4 / 9, Φ6 / 12, Φ9 / 18 , Φ12 / 24 and other specifications. MoSi2 heating element at high temperature oxidizing atmosphere, surface will produce quartz protective layer to prevent it to continue oxidation. When the element temperature is higher than 1700 ℃, quartz protective layer will melt. If the heating element is still used in oxidizing atmosphere, the quartz protective layer will rebuild. Besides, u-shaped silicon molybdenum rod should not be long-term use at low temperature (400-700 ℃), otherwise it will break due to oxidation.

If you have got any interest in molybdenum metals, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.

Related Links: Molybdenum News & Prices