Molybdenum Disilicide Specification

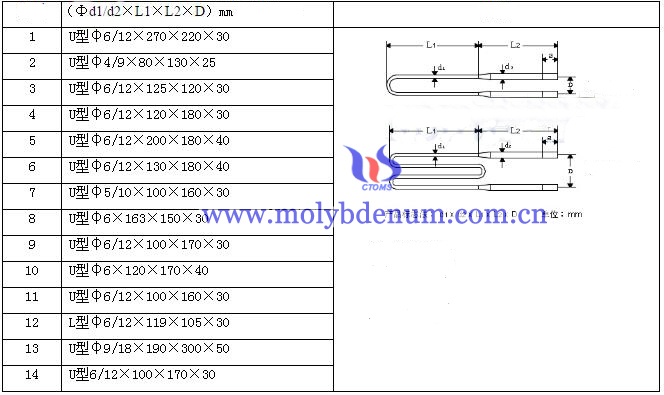

Molybdenum disilicide specification is following (d1x / d2): Φ3 / 6, Φ4 / 9, Φ6 / 12, Φ9 / 18, Φ12 / 24 and so on. Common specification is Φ6 / 12 and Φ9 / 18 two kinds. Molybdenum disilicide (silicon molybdenum rod) has hot end for heating and cold end for electrical. The cold end has bigger diameter than hot end, which can avoid the wiring portion burn by high temperature. Silicon molybdenum rod commonly used in high-temperature resistance furnace and the size of hot end and cold end generally determine by the high of furnace hearth and the wall thickness of the furnace wall.

For small-scale experimental furnace, the furnace hearth is small, so the operation temperature is about 1500 ℃ and the power is not too large, generally used hot end 6mm and cold end 12mm silicon molybdenum rod. If the electric furnace is small usually used Φ3/6 molybdenum disilicide and this is mainly depending on the size of the furnace. For large furnace molybdenum disilicide selection should focus operation temperature, service power and the length of the furnace hearth, and usually selected Φ9 / 18.

Silicon molybdenum rod has different types including straight bar, U-shaped, W-shaped and L-shaped. In addition, Chinatungsten also produces other molybdenum disilicide customize shape including tube, thermocouple protection tube and probes and so on.

If you have got any interest in molybdenum metals, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.

Related Links: Molybdenum News & Prices