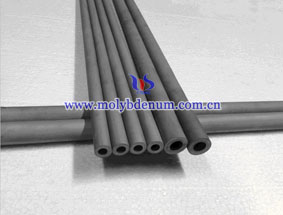

Molybdenum Disilicide Protective Tube

Molybdenum disilicide protective tube has difficult producing process, so the yield is low, but the product has long service life. During the preparation, the molybdenum disilicide powder should be pressed to shape up, and then after sintering, testing and other processes we can obtain molybdenum disicilide tube. Common specification of molybdenum disilicide tube is 10-35mm diameter and wall thickness 5-10mm. Wall thickness less than 5mm will easy to split and has short service life, so we do not recommend producing 5mm or less wall thickness molybdenum disilicide tube.

Molybdenum disilicide protection tube product standard method: MS / D / d / L. D is protective tube diameter and d is inner diameter. L is length and the unit is mm. This product is an extension product of molybdenum disilicide heating element and the materials and the raw materials is similar to silicon molybdenum rod. Molybdenum disilicide protection tube has high temperature anti-oxidation, good corrosion resistance, good thermal stability and melting point and other good prroperties.

Molybdenum disilicide protection tube is kind of metal ceramic protective tube and it can isolate thermocouples or other heating element from working conditions and extend the service life of thermocouple and other heating elements. Molybdenum disilicide bubbling tube is high temperature material fall in between of metal and ceramic, developed on the basis of molybdenum disicilide material. Compared with other molybdenum disicilide products it has better thermal shock resistance, oxidation resistance, air tightness, mechanical properties, high temperature resistance and good thermal stability, which is suitable used in oxidation, reduction, oxidation and reduction alternately, chemical etching gas, molten metal and other media environment. And it as protection tube for natural gas, fertilizer, petrochemical, coal chemical industry is better than other types of protective tube.

Molybdenum disilicide should not be prolonged use in 400-700℃, because it will easily oxidized. At 1350℃ molybdenum disilicide will soften, so the molybdenum disilicide protection tube should install by vertically.

If you have got any interest in molybdenum metals, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.

Related Links: Molybdenum News & Prices