Molybdenum Silicide

Molybdenum silicide (molybdenum disilicide) developed in 1906 and it has high temperature oxidation resistance. Silicon and molybdenum under different conditions can form Mo3Si, Mo5Si3 and MoSi2 these three compounds. Among these compounds molybdenum disilicide has most widely used. It is a Dalton inter-metal compound and its crystal structure atom bonding exhibits metallic and covalent coexistence features. MoSi2 has excellent high temperature oxidation resistance. MoSi2 has widely applications and it is mainly used as heating elements, oxidation coatings and structural parts used in various fields.

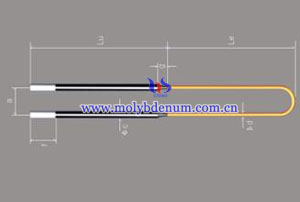

Molybdenum silicide applications: 1. Energy chemical industry: electric heating elements, high-temperature nuclear reactor heat exchanger device, gas burner, high temperature thermocouple protection tube and crucible smelting vessel (used for melting sodium, lithium, lead, bismuth, tin, and other metals). 2. Microelectronics industry: MoSi2 and some other refractory metal silicide Ti5Si3, WSi2, TaSi2 is LSI gate and interconnect film important material. 3. Aerospace industry: as high temperature oxidation resistant coating materials have been extensive application and deep research, especially as turbine engine components, such as material blades, impellers, combustor, and nozzle and seal apparatus. 4 Automotive: automotive turbocharger rotor turbine engine, the valve body, the spark plug and engine parts.

Physical and chemical properties of molybdenum silicide:

| Molecular formula | MoSi2 |

| Melting point | 2030℃ |

| Density | 6.28g/cm |

| Resistivity | 21.5x10-6Ω·cm |

| Thermal conductivity | 45W/mK |

| Coefficient of thermal expansion | 7.8x10/K |

If you have got any interest in molybdenum metals, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.

Related Links: Molybdenum News & Prices