Molybdenum Disilicide Application

Molybdenum disilicide application is widely. Molybdenum disilicide having high melting point, high temperature oxidation resistance and thermal shock resistance and stable resistance characteristics, primarily as high temperature structural materials and heating element material used in various different fields.

Molybdenum disilicide as structural material is usually made of high temperature components used in aerospace and automotive gas turbine. Besides, it is also made of gas burners, nozzle, high temperature filters and spark plugs. Currently, it has become the intermetallic compound structure material research focus and the biggest problem of it is room temperature brittleness.

![]()

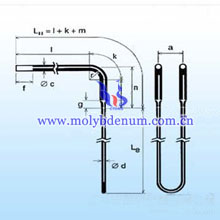

In the 1960s, molybdenum disilicide was made of MoSi2 heating elements widely used in industrial fields. Molybdenum silicon rod can be used in more than 1773K air environment, commonly used in the glass industry, electronic industry, metallurgical industry, ceramic industry and other fields. With the development of science and technology, in the early 1980s, molybdenum disilicide got corresponding improvement, Japanese researchers produced molybdenum disilicide phase matrix composites, which improved its high temperature deformation ability, so it can use in some harsh conditions. In the 1990s, the molybdenum disilicide got further improvement to produce heating element which can use in 2173K. This heating element is kind of solid solution composite materials, having good high temperature deformation resistance and high temperature resistance, which is benefit of MoSi2 and WSi2 complete solution characteristics and WSi melting point is higher than MoSi2’s. With the aerospace putted forward higher requirements on high temperature structural materials, the molybdenum disilicide based materials had been developed. It not only improves molybdenum disilicide room temperature brittle, but also improves its low temperature strength and high temperature creep and other shortcomings, so molybdenum disilicide based material’s application range is wider. Further, in order to meet molybdenum disilicide in mobile phones, laptops and other electronic products’ application, the researchers from the low-temperature oxidation principle developed low temperature oxidation resistant molybdenum disilicide composite material and it is usually made of heating element used in semiconductors manufacturing and the market is constantly expanding.

If you have got any interest in molybdenum metals, please feel free to contact us by email: sales@chinatungsten.com, sales@xiamentungsten.com or by telephone:86 592 512 9696/86 592 512 9595.

Related Links: Molybdenum News & Prices